Introduction

A Factory Automation MES for the semiconductor industry is a specialized software layer that sits between the enterprise-level ERP and the physical shop floor equipment. It provides real-time monitoring, tracking, and control of the entire wafer fabrication process. Unlike general-purpose manufacturing software, a semiconductor MES must handle extreme data volumes, complex “recipes,” and strict “Time-to-Result” (TTR) requirements. It essentially acts as the “brain” of the factory, orchestrating everything from robotic wafer transport to chemical vapor deposition.

The importance of these tools is driven by the sheer cost of failure; a single contaminated batch can result in millions of dollars in losses. Key real-world use cases include Full Traceability (tracking a single die back to its original wafer and lot), Yield Management (identifying patterns in defects), and Advanced Process Control (automated adjustment of machines based on real-time sensor data). When choosing a tool, evaluators should prioritize “Lot and Wafer” level tracking, integration with SEMI standards (SEC/GEM), and the ability to scale to handle billions of data points daily.

Best for: Integrated Device Manufacturers (IDMs), pure-play foundries, and Outsourced Semiconductor Assembly and Test (OSAT) facilities that require 24/7 uptime and rigorous compliance tracking.

Not ideal for: Research labs with low-volume prototyping needs or general discrete manufacturers (like furniture or textile makers) who do not require the specialized cleanroom and wafer-handling logic native to these systems.

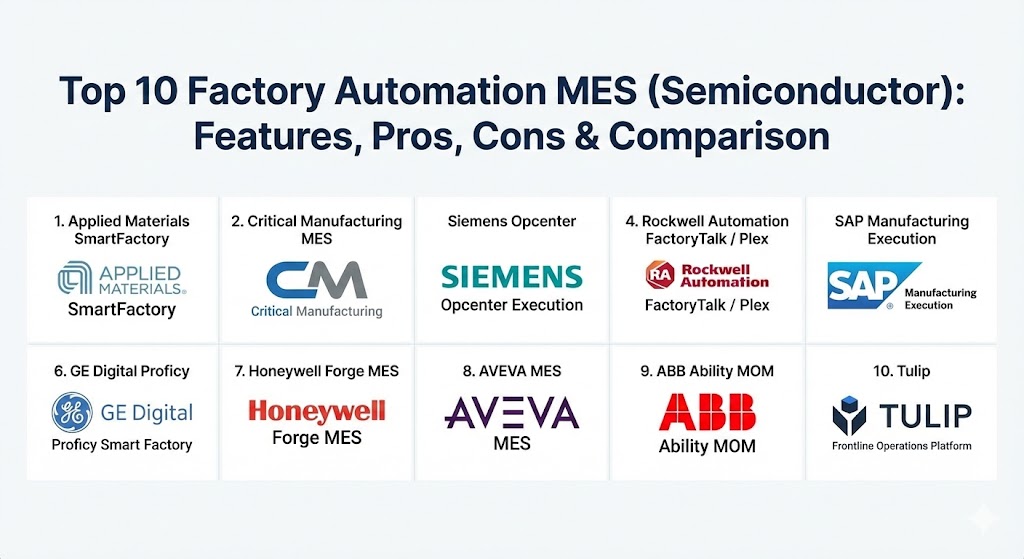

Top 10 Factory Automation MES (Semiconductor) Tools

1 — Applied Materials: Applied SmartFactory

Applied Materials is the titan of the semiconductor space. Their SmartFactory suite is arguably the most dominant MES on the planet, specifically engineered for high-volume, leading-edge Fabs.

- Key features:

- Advanced Productivity Suite for automated scheduling and dispatching.

- Native integration with Applied Materials hardware and sensors.

- High-fidelity digital twin for factory-wide simulation.

- Real-time Fault Detection and Classification (FDC).

- Integrated Maintenance Management to minimize unscheduled downtime.

- Advanced Process Control (APC) with machine learning optimization.

- Pros:

- Unrivaled reliability with a proven track record of “five nines” (99.999%) uptime.

- The most comprehensive “out-of-the-box” library for semiconductor-specific workflows.

- Cons:

- Extremely high cost; generally accessible only to top-tier enterprise Fabs.

- Implementation is a massive undertaking that requires specialized consultants.

- Security & compliance: NIST 800-53, SOC 2, and rigorous hardware-level security protocols for cleanroom environments.

- Support & community: World-class global support network with dedicated on-site engineering options and a massive ecosystem of certified experts.

2 — Critical Manufacturing: Critical Manufacturing MES

Designed specifically for high-tech industries, Critical Manufacturing (a subsidiary of ASMPT) offers what is widely considered the most modern and flexible MES for “Industry 4.0” semiconductor facilities.

- Key features:

- Native support for complex wafer-level and die-level genealogy.

- Integrated IIoT platform for seamless equipment connectivity.

- Advanced “Experiment Management” for R&D within the production line.

- Graphical 3D factory digital twin for real-time visualization.

- Mobile-first architecture for cleanroom-compatible tablets.

- Built-in SPC (Statistical Process Control) and Exception Management.

- Pros:

- The most intuitive and modern user interface in the industry.

- Exceptionally flexible and modular, making it easier to upgrade than legacy systems.

- Cons:

- Newer to the market compared to incumbents like Applied or Siemens.

- Rapid growth has occasionally led to wait times for specialized support resources.

- Security & compliance: ISO 27001, GDPR, HIPAA, and support for 21 CFR Part 11 requirements.

- Support & community: High customer satisfaction ratings; strong online documentation and a growing global partner network.

3 — Siemens: Opcenter Execution Semiconductor

Formerly known as Camstar, Opcenter Execution Semiconductor is a veteran platform that has powered some of the world’s most advanced Fabs for decades. It is part of the massive Siemens Xcelerator portfolio.

- Key features:

- Deep support for both Front-End (Fab) and Back-End (Assembly/Test).

- Integrated electronic Device History Records (eDHR).

- High-performance transaction engine capable of multi-site synchronization.

- Native integration with Siemens PLM (Teamcenter) and Automation hardware.

- Advanced Quality Management for root cause analysis.

- Robust recipe management with automated version control.

- Pros:

- Unmatched global footprint; if you have a Fab, there is a Siemens tech nearby.

- Highly stable and “hardened” through decades of real-world use.

- Cons:

- The legacy architecture can make customizations time-consuming.

- Transitioning from Camstar to the modern Opcenter platform can be a complex migration.

- Security & compliance: IEC 62443 (Industrial Cybersecurity), SOC 2, and ISO 9001/13485 compliance.

- Support & community: Massive global support infrastructure, Siemens “Xcelerator” community, and formal training academies worldwide.

4 — Rockwell Automation: FactoryTalk / Plex

Rockwell Automation offers two paths: the heavy-duty FactoryTalk for traditional on-premise Fab control, and Plex for cloud-native, SaaS-based backend assembly and testing operations.

- Key features:

- Plex Smart Manufacturing Platform for cloud-based multi-site visibility.

- FactoryTalk ProductionCentre for complex, high-concurrency on-premise logic.

- Integrated Asset Performance Management (APM).

- Native connectivity to Allen-Bradley PLCs and sensors.

- Advanced workforce enablement through AR (Augmented Reality).

- Real-time energy monitoring to track the carbon footprint of production.

- Pros:

- Plex is the clear leader for OSATs wanting a rapid, cloud-first deployment.

- Excellent integration for Fabs that rely heavily on Rockwell hardware.

- Cons:

- FactoryTalk can feel “industrial” and less “high-tech” than Critical Manufacturing.

- SaaS models (Plex) may face resistance from Fabs requiring 100% offline isolation.

- Security & compliance: NIST-aligned audit trails, SOC 2 Type II, and ITAR compliance for defense-related chips.

- Support & community: Extensive US-based support, the THWACK community, and a huge network of systems integrators.

5 — SAP: SAP Manufacturing Execution (ME)

For enterprises already running their business on SAP S/4HANA, SAP ME is the natural choice to provide a “single source of truth” from the shop floor to the boardroom.

- Key features:

- Seamless integration with SAP ERP for real-time financial and inventory sync.

- Global multisite centralized management.

- Sophisticated WIP (Work in Progress) tracking and serialized data management.

- Integrated labor management and training certification tracking.

- Automated non-conformance management (NC) workflows.

- Advanced data archiving for long-term regulatory compliance.

- Pros:

- Best-in-class for global supply chain visibility and financial reporting.

- Massive ecosystem of consultants ensures you can always find help.

- Cons:

- Notoriously expensive and complex to implement.

- Can feel “ERP-heavy,” sometimes lacking the agile responsiveness of specialized tools.

- Security & compliance: GDPR, ISO 27001, and top-tier enterprise encryption standards.

- Support & community: Unmatched global support network, SAP Community blogs, and formal SAP Training certifications.

6 — GE Digital: Proficy Smart Factory

GE Digital’s Proficy suite is a reliable, high-availability MES that excels in process-heavy manufacturing, making it a strong contender for the chemical-heavy stages of semiconductor fabrication.

- Key features:

- Proficy Plant Applications for complex batch and process logic.

- Integrated Efficiency Analysis (OEE) and downtime tracking.

- Powerful “Process Analysis” module for identifying yield bottlenecks.

- Native integration with GE Vernova cloud and edge services.

- Cloud-ready but with robust on-premise local survivability.

- Pros:

- Exceptionally stable architecture; designed for 24/7 industrial uptime.

- Strong “all-in-one” foundation for companies using GE’s automation stack.

- Cons:

- Lacks some of the “wafer-specific” UI features found in camstar or Applied.

- The user interface can feel dated compared to newer SaaS rivals.

- Security & compliance: SOC 2, ISO 27001, and AWS Industrial Software Competency.

- Support & community: Mature enterprise support with deep roots in industrial manufacturing.

7 — Honeywell: Honeywell Forge MES

Honeywell Forge is an “Enterprise Performance Management” platform that incorporates MES functionality with a heavy focus on AI-driven optimization and sustainability.

- Key features:

- AI-powered predictive maintenance and yield optimization.

- Sustainability dashboards for tracking water and chemical usage.

- Unified portal for multi-site operational excellence.

- Advanced cybersecurity monitoring for the OT (Operational Technology) layer.

- Mobile-enabled for remote monitoring by plant managers.

- Pros:

- Leading-edge AI capabilities that go beyond simple data tracking.

- Excellent for Fabs prioritizing “Green” manufacturing and carbon reduction.

- Cons:

- High entry price; primarily targeted at the largest global enterprises.

- Can be overly broad if you only need basic floor control.

- Security & compliance: Multi-factor authentication, end-to-end encryption, and full audit trails.

- Support & community: Global tech giant support with a strong focus on high-reliability industrial sectors.

8 — AVEVA: AVEVA MES

AVEVA (formerly Schneider Electric Software) provides a model-driven MES that focuses on standardizing processes across a global network of factories.

- Key features:

- Model-driven architecture for rapid multi-site rollouts.

- Integrated “Inventory Management” and tracking.

- Powerful workflow engine for automating human-centric tasks.

- Native integration with AVEVA System Platform (formerly Wonderware).

- Rich visualization and OEE (Overall Equipment Effectiveness) dashboards.

- Pros:

- Best choice for companies looking to “standardize” different Fabs under one logic.

- Very strong visual tools for designing and deploying workflows.

- Cons:

- Heavily optimized for the Schneider/AVEVA ecosystem; third-party hardware integration can vary.

- Scaling the database for high-volume Front-End Fabs requires expert tuning.

- Security & compliance: Role-based access, full encryption, and ISO-aligned security controls.

- Support & community: Comprehensive world-class training and a massive global Knowledge & Support Center.

9 — ABB: ABB Ability MOM

ABB Ability Manufacturing Operations Management (MOM) is an integrated suite that bridges the gap between the DCS (Distributed Control System) and the ERP.

- Key features:

- Unified platform for operations, maintenance, and quality.

- Advanced “Integration Bus” for connecting disparate IT/OT systems.

- Real-time material and inventory tracking.

- Intelligent alarm management to prevent “alert fatigue” for operators.

- Comprehensive reporting and analytics for yield trends.

- Pros:

- Excellent for high-concurrency environments where hardware integration is key.

- Highly reliable; built on decades of ABB’s industrial automation heritage.

- Cons:

- Often requires a deep commitment to the ABB automation ecosystem.

- Documentation for semiconductor-specific configurations is less public than competitors.

- Security & compliance: High-level cybersecurity focus, automated compliance checks, and IEC 62443 certified.

- Support & community: Mature manufacturing solutions for large enterprises with a focus on long-term lifecycle support.

10 — Tulip: Frontline Operations Platform

Tulip represents the “new wave” of MES—a no-code, cloud-native platform that focuses on the “Connected Worker” rather than just machine data.

- Key features:

- No-code app builder for creating custom operator interfaces.

- Integrated Computer Vision for automated quality inspection.

- Native edge connectivity for IoT-enabled cleanroom sensors.

- Real-time data visualization and “self-service” analytics.

- Agile deployment that can start in one “cell” and scale out.

- Pros:

- The lowest barrier to entry and fastest “Time-to-Value.”

- Extremely popular for Backend assembly and manual cleanroom tasks.

- Cons:

- Not designed to handle the massive, low-latency SCADA requirements of Front-End Wafer Fabs.

- Compliance validation for SaaS in “Hard-Regulated” Fabs can be an hurdle.

- Security & compliance: SOC 2 Type II, GDPR, and GxP environment support.

- Support & community: Vibrant “Tulip Community” site, free University training, and modern chat-based support.

Comparison Table

| Tool Name | Best For | Platform(s) Supported | Standout Feature | Rating (Gartner Peer Insights) |

| Applied SmartFactory | High-Volume Fab | Windows, Linux | 99.999% Uptime SLA | 4.8 / 5 |

| Critical Manufacturing | Industry 4.0 / UI | Cloud, On-Prem, Hybrid | 3D Digital Twin | 4.9 / 5 |

| Siemens Opcenter | Global Legacy Fabs | Windows, Cloud | Camstar Heritage | 4.4 / 5 |

| Rockwell Automation | Backend / SaaS | Cloud (Plex), Windows | AR Workforce Integration | 4.3 / 5 |

| SAP ME | ERP Integration | Windows, Cloud | Single-Source S/4HANA Sync | 4.1 / 5 |

| GE Proficy | Process Stages | Windows, Cloud | Industrial Reliability | 4.2 / 5 |

| Honeywell Forge | Sustainability / AI | SaaS, Hybrid | AI Yield Forecasting | 4.5 / 5 |

| AVEVA MES | Standardization | Windows, Cloud | Model-Driven Workflow | 4.3 / 5 |

| ABB Ability MOM | IT/OT Integration | Industrial Cloud | Integrated Service Bus | 4.3 / 5 |

| Tulip | Connected Worker | SaaS, Cloud | No-Code App Builder | 4.7 / 5 |

Evaluation & Scoring of Factory Automation MES (Semiconductor)

Evaluating a semiconductor MES is a weighted process where reliability often outweighs the latest flashy features.

| Category | Weight | Evaluation Criteria |

| Core Features | 25% | Wafer/Die tracking, SECS/GEM connectivity, SPC, and yield analysis. |

| Ease of Use | 15% | Operator UI intuitiveness, dashboard clarity, and “no-code” capabilities. |

| Integrations | 15% | Depth of API, ERP compatibility (SAP/Oracle), and PLC connectivity. |

| Security & Compliance | 10% | Encryption, SOC 2, ISO 27001, and cleanroom data isolation. |

| Performance | 10% | Transaction speed, database scaling, and “Five Nines” uptime availability. |

| Support & Community | 10% | Quality of documentation, speed of support, and global partner network. |

| Price / Value | 15% | TCO vs. Yield improvement and reduction in manual data entry. |

Which Factory Automation MES (Semiconductor) Tool Is Right for You?

Selecting the right tool depends on your facility’s scale and your current “technical debt.”

- For Enterprise IDMs (Front-End Fab): You cannot afford a single second of downtime. Applied SmartFactory and Siemens Opcenter are the gold standards for high-volume wafer fabrication.

- For High-Tech “Smart” Fabs: If you want a modern, visually-driven system that is ready for the future of AI and 3D modeling, Critical Manufacturing is the industry favorite for 2026.

- For OSAT & Backend Assembly: Speed and flexibility are key. Plex (Rockwell) and Tulip are excellent for these facilities where the logic is less about “wafer chemistry” and more about “logistics and assembly.”

- For Global Enterprises: If your goal is to have every factory in the world appear on one SAP dashboard, SAP ME is the logical path, despite its high implementation cost.

- Budget vs. Reliability: If you need a stable, proven industrial system without the “brand premium” of Applied Materials, GE Digital Proficy and ABB Ability offer incredible reliability and deep hardware integration.

Frequently Asked Questions (FAQs)

1. What makes a “Semiconductor” MES different from a general MES? Semiconductor MES must handle specialized logic like “Wafer Slots,” “Cassolette Management,” and complex chemical “Recipes.” They must also speak the SECS/GEM language used by cleanroom equipment.

2. Is Cloud-based MES safe for a Fab? While many Fabs prefer “Air-gapped” on-premise systems for security, modern cloud MES (like Plex or Critical Manufacturing) offer high-level security that often exceeds what a local IT team can provide.

3. What is SECS/GEM? It stands for SEMI Equipment Communications Standard / Generic Equipment Model. It is the universal communication protocol used by semiconductor equipment to talk to the MES.

4. Can an MES help improve my “Yield”? Yes. By using real-time Statistical Process Control (SPC) and AI, an MES can detect when a process is “drifting” and alert engineers before it results in defective chips.

5. How long does a typical implementation take? For a large Fab, expect 12–24 months. For a smaller Backend assembly plant using a SaaS tool like Tulip, you can be up and running in 3–6 months.

6. Do these tools support “Paperless” cleanrooms? Yes. Modern MES platforms replace “Paper Travelers” with electronic Device History Records (eDHR), allowing operators to use tablets or voice commands within the cleanroom.

7. Can I use these tools for R&D? Tools like Critical Manufacturing have specific “Experiment Management” modules that allow you to run R&D lots alongside production lots without disrupting the main line.

8. What is “Lot and Wafer Genealogy”? It is the ability to track every single event that happened to a specific wafer—from the day it was a raw silicon slice to the day it became a finished processor.

9. Are these tools compatible with AI and Machine Learning? Yes. Most modern platforms (especially Honeywell and Applied) use AI to analyze “Big Data” from the tools to predict when a component is about to fail.

10. What is the ROI of an MES? ROI comes from reduced yield loss, faster cycle times, and automated compliance. For a large Fab, a 1% yield improvement can pay for the entire MES in less than a year.

Conclusion

In the semiconductor industry, the MES is no longer just a “recording device”—it is the engine of competitiveness. As we move deeper into 2026, the gap between “Digital Fabs” and legacy manual operations will only widen. Choosing the right tool requires a balance between the reliability of the past and the flexibility of the future. The “best” choice is the one that aligns with your hardware stack, your team’s technical expertise, and your ultimate goals for yield and scale.