Introduction

Product Lifecycle Management (PLM) is a strategic business approach that manages a product’s entire journey from initial ideation and design through engineering, manufacturing, service, and eventual disposal. At its core, a PLM tool serves as a “single source of truth,” ensuring that everyone from the design engineer to the procurement officer is working with the most current data. By centralizing information, these tools eliminate silos, reduce time-to-market, and prevent costly manufacturing errors caused by outdated revisions.

Key real-world use cases include managing the complex “Digital Thread” of an electric vehicle, tracking regulatory compliance for medical devices, and orchestrating global collaboration for electronics manufacturers. When evaluating PLM tools, users should look for robust Bill of Materials (BOM) management, seamless CAD integration, advanced change control workflows, and the ability to scale from initial prototyping to high-volume production.

Best for: Engineering-intensive industries such as aerospace, automotive, medical devices, and high-tech electronics. It is essential for mid-market to enterprise companies where cross-functional collaboration and strict regulatory compliance are non-negotiable.

Not ideal for: Service-based businesses, pure software startups (where ALM/Jira might suffice), or very small retail shops that sell finished goods without performing internal design or complex manufacturing.

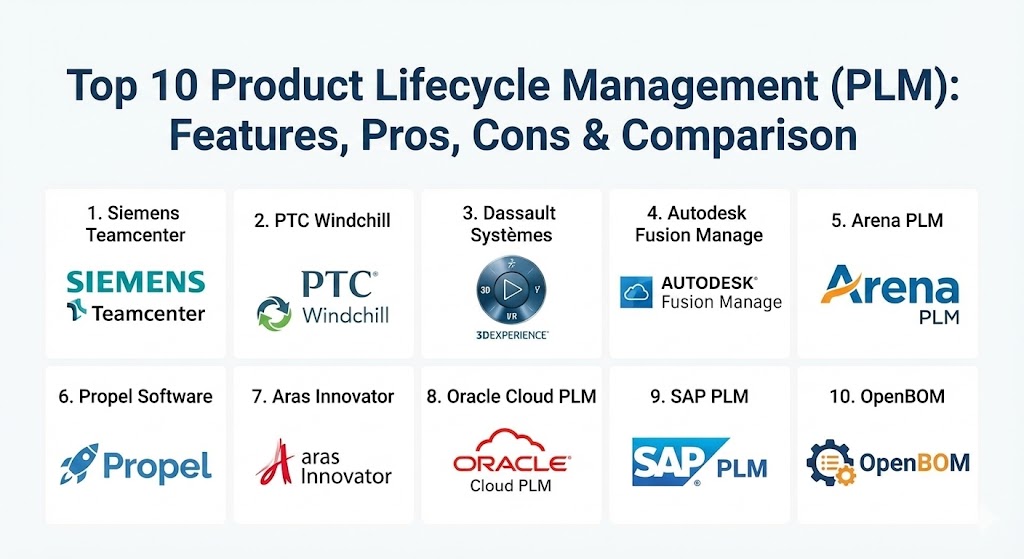

Top 10 Product Lifecycle Management (PLM) Tools

1 — Siemens Teamcenter

Siemens Teamcenter is widely considered the global industry standard for PLM. It provides a massive, scalable suite designed to handle the most complex engineering challenges, from aircraft engines to high-speed trains.

- Key features:

- Comprehensive Bill of Materials (BOM) management across EBOM and MBOM.

- Deep integration with nearly all major CAD tools (NX, Solid Edge, CATIA, Creo).

- Advanced Digital Twin simulation and digital thread capabilities.

- Integrated requirements management and systems engineering.

- Robust sustainability and environmental compliance tracking.

- Supplier collaboration portals for secure data exchange.

- Pros:

- Unmatched scalability; it can manage millions of parts and thousands of users.

- The most mature and stable feature set in the PLM market.

- Cons:

- High total cost of ownership (TCO) including licensing and implementation.

- Steep learning curve requiring dedicated administrators and extensive training.

- Security & compliance: ISO 27001, SOC 2, GDPR, ITAR, and HIPAA compliant. Includes advanced military-grade encryption and granular audit logs.

- Support & community: World-class enterprise support, massive global user groups (Siemens PLM World), and an exhaustive online documentation library.

2 — PTC Windchill

PTC Windchill was the first web-based PLM system and remains a powerhouse for discrete manufacturers who prioritize smart, connected product development and IoT integration.

- Key features:

- Native integration with Creo and multi-CAD data management.

- Advanced change and configuration management workflows.

- ThingWorx integration for connecting real-time IoT data to the PLM.

- Vuforia integration for Augmented Reality (AR) design reviews.

- Quality management system (QMS) integration for closed-loop quality.

- Cloud-first architecture with the new Windchill+ SaaS offering.

- Pros:

- Excellent web-native performance that makes it easy for remote teams to access.

- Strongest “Industry 4.0” vision with its AR and IoT capabilities.

- Cons:

- Can be difficult to customize without specialized PTC-certified consultants.

- User interface can feel dense for non-engineering users.

- Security & compliance: SOC 2 Type II, ISO 27001, HIPAA, and support for CMMC (Cybersecurity Maturity Model Certification).

- Support & community: High-quality 24/7 technical support and a large developer community centered around the PTC Atlas platform.

3 — Dassault Systèmes 3DEXPERIENCE (Enovia)

The 3DEXPERIENCE platform, powered by Enovia, offers a holistic approach to PLM, focusing on “social collaboration” and immersive 3D design environments.

- Key features:

- Unified data model for CAD (CATIA, SolidWorks) and PLM processes.

- Holistic 3D model collaboration through the 3DEXPERIENCE Compass.

- Advanced product configuration and variant management.

- Integrated simulation and manufacturing planning (SIMULIA/DELMIA).

- Project and portfolio management (PPM) directly linked to product data.

- Virtual testing and validation environments.

- Pros:

- Perfect for companies already deep in the Dassault ecosystem (CATIA users).

- Exceptional visual collaboration tools that bring designs to life.

- Cons:

- Transitioning from legacy Enovia to the 3DEXPERIENCE platform can be complex.

- High barrier to entry for companies not using Dassault CAD tools.

- Security & compliance: ISO 27001, SOC 2, and GDPR compliant; high-tier data encryption for cloud users.

- Support & community: Extensive global support and professional training through a massive partner network.

4 — Autodesk Fusion Manage

Fusion Manage is a cloud-native PLM solution designed to be “PLM for the rest of us.” It focuses on simplicity, rapid deployment, and tight integration with the Autodesk Fusion ecosystem.

- Key features:

- Pre-configured “apps” for NPI, Change Management, and Quality.

- Native integration with Fusion 360 and Autodesk Vault.

- Flexible workflow engine with a visual designer.

- Real-time dashboards and KPIs for product health.

- Integrated Supplier Management and Item Cataloging.

- Automatic versioning and revision control.

- Pros:

- Much more affordable and faster to implement than legacy systems.

- Modern, browser-based UI that is intuitive for new users.

- Cons:

- Lacks the deep systems engineering depth found in Teamcenter or Windchill.

- Best suited for mid-market; may struggle with extremely high-complexity aerospace BOMs.

- Security & compliance: SOC 2, ISO 27001, and GDPR compliant. Backed by Autodesk’s secure cloud infrastructure.

- Support & community: Excellent online tutorials, video documentation, and a very active community forum.

5 — Arena PLM (by PTC)

Arena PLM is a pioneer in the SaaS PLM space, specifically tailored for electronics and high-tech manufacturers who rely on distributed global supply chains.

- Key features:

- Unified PLM and Quality Management (QMS) in a single SaaS platform.

- World-class Bill of Materials (BOM) and Change Management.

- Real-time supplier collaboration and sourcing visibility.

- Integrated SiliconExpert and Octopart for electronic component data.

- Regulatory compliance tracking (RoHS, REACH, Conflict Minerals).

- Rapid NPI (New Product Introduction) workflows.

- Pros:

- Zero-footprint SaaS; no servers to manage and very fast to go live.

- Specifically built for the electronics industry with component database integrations.

- Cons:

- Less focus on heavy mechanical “3D CAD” management compared to its parent, Windchill.

- Customization is more restricted compared to on-premise platforms.

- Security & compliance: SOC 2 Type II, ISO 27001, FDA 21 CFR Part 11, and GDPR.

- Support & community: Proactive customer success managers and a highly-regarded “Arena University” for user training.

6 — Propel Software

Propel is a unique cloud-native PLM built entirely on the Salesforce platform, creating a seamless digital thread that connects product development to sales and customer service.

- Key features:

- Native integration with Salesforce CRM and Service Cloud.

- Unified PLM, QMS, and PIM (Product Information Management).

- Product-centric collaboration using Salesforce Chatter.

- Highly configurable dashboards and reporting.

- Customer feedback loops integrated directly into engineering changes.

- Training and document control for regulated industries.

- Pros:

- Incredible ease of use for anyone already familiar with the Salesforce UI.

- Bridges the gap between “back-office” engineering and “front-office” sales.

- Cons:

- Requires a Salesforce environment, which may be a hurdle for some IT departments.

- Not as deep in traditional CAD data management as engineering-focused PLMs.

- Security & compliance: Inherits Salesforce’s world-class security; SOC 1/2/3, GDPR, HIPAA, and ISO 27001.

- Support & community: Access to the massive Salesforce Trailhead community and enterprise-grade support.

7 — Aras Innovator

Aras disrupted the market with an “open-release” model, offering a highly flexible, low-code platform that companies can customize to an extreme degree.

- Key features:

- Low-code platform for building custom PLM applications.

- High-performance Multi-CAD management.

- Advanced configuration management and “digital thread” tracking.

- Secure, scalable architecture for both cloud and on-premise.

- Visual collaboration with CAD markup and commenting.

- Subscription model includes all upgrades, even for highly customized systems.

- Pros:

- The most customizable PLM on the market; it fits the business, not the other way around.

- Unique “no-fee” base software model with paid enterprise subscriptions.

- Cons:

- Requires internal technical skills to take full advantage of the platform’s flexibility.

- Not as many “out-of-the-box” features as competitors.

- Security & compliance: ISO 27001, SOC 2, and ITAR support; highly secure database-level permissions.

- Support & community: Very active developer community and a subscription-based support model that is highly rated for technical depth.

8 — Oracle Cloud PLM

Oracle’s PLM solution is part of their broader Cloud SCM (Supply Chain Management) suite, designed for global enterprises that need a direct link between innovation and execution.

- Key features:

- Integrated Innovation Management for ideation and portfolio selection.

- Native connection to Oracle Cloud ERP and SCM.

- Advanced analytics and AI-driven insights for product risk.

- Comprehensive Quality Management and Master Data Management (MDM).

- “Digital Thread” visibility from design to shop floor.

- Configurator modeling for complex, engineered-to-order products.

- Pros:

- Best-in-class for companies already using Oracle for their ERP or Supply Chain.

- Powerful predictive analytics for assessing cost and quality risks early.

- Cons:

- Can feel overly complex for smaller, engineering-only teams.

- Implementation typically requires a large consulting engagement.

- Security & compliance: SOC 1/2, ISO 27001, GDPR, and HIPAA compliant.

- Support & community: Massive enterprise support network and extensive formal training through Oracle University.

9 — SAP Product Lifecycle Management

SAP PLM is the logical choice for the thousands of global enterprises that run on the SAP S/4HANA backbone, focusing on a seamless engineering-to-production handoff.

- Key features:

- Seamless handoff from Engineering BOM (EBOM) to Manufacturing BOM (MBOM).

- Integrated Portfolio and Project Management (PPM).

- Advanced recipe management for process industries (Food, Pharma).

- Native integration with SAP Production Planning and Quality Management.

- Integrated sustainability and carbon footprint tracking.

- Visual enterprise tools for 3D visualization without CAD software.

- Pros:

- Eliminates the data gap between the design office and the factory floor.

- Strongest solution for process industries (specification and recipe management).

- Cons:

- Often requires a deep understanding of the SAP ecosystem to manage.

- The UI can be intimidating for casual users compared to SaaS-only tools.

- Security & compliance: Adheres to the highest global security standards; SOC 2, ISO 27001, and GDPR.

- Support & community: Infinite support resources through the global SAP ecosystem and Sapphire user groups.

10 — OpenBOM

OpenBOM is a modern, collaborative workspace designed for engineering teams and small manufacturers who need a lightweight, flexible way to manage BOMs and parts.

- Key features:

- Real-time “Google Docs-style” collaboration on Bills of Materials.

- One-click BOM generation from CAD (SolidWorks, Fusion 360, etc.).

- Integrated inventory and purchase order management for small shops.

- Multi-level BOM management with automatic cost roll-ups.

- Change history and revision management.

- Cloud-based and mobile-accessible.

- Pros:

- Extremely fast to set up; teams can be productive in minutes, not months.

- Very affordable pricing for startups and small businesses.

- Cons:

- Lacks the deep lifecycle “governance” and systems engineering of enterprise PLM.

- Not designed for massive, multi-site enterprise organizations.

- Security & compliance: Standard cloud encryption; GDPR compliant.

- Support & community: Strong online documentation, video tutorials, and a very active user forum.

Comparison Table

| Tool Name | Best For | Platform(s) Supported | Standout Feature | Rating (Gartner) |

| Siemens Teamcenter | Large Enterprises | Windows, Linux, Cloud | Industry-Leading Scalability | 4.8 / 5 |

| PTC Windchill | Smart Connected Products | Web-Native, SaaS | AR & IoT Integration | 4.7 / 5 |

| Dassault Enovia | 3D-Centric Design | 3DEXPERIENCE Cloud | Immersive 3D Collaboration | 4.6 / 5 |

| Autodesk Fusion Manage | Mid-Market Ease of Use | Cloud / Browser | Rapid “App-Based” Deployment | 4.3 / 5 |

| Arena PLM | Electronics / High-Tech | SaaS | Multi-Tier Supplier Sourcing | 4.6 / 5 |

| Propel Software | Salesforce Ecosystem | Salesforce Cloud | PLM-CRM Convergence | 4.7 / 5 |

| Aras Innovator | Extreme Customization | Windows, Linux, Cloud | Low-Code Platform Agility | 4.5 / 5 |

| Oracle Cloud PLM | Oracle ERP Users | Oracle Cloud | Integrated Innovation Mgmt | 4.1 / 5 |

| SAP PLM | Process Industries | SAP S/4HANA | Engineering-to-Factory Handoff | 4.0 / 5 |

| OpenBOM | Startups & Small Teams | SaaS | Real-time BOM Collaboration | 4.6 / 5 |

Evaluation & Scoring of Product Lifecycle Management (PLM)

When selecting a PLM, organizations should weigh their needs against these standard industry benchmarks.

| Category | Weight | Evaluation Criteria |

| Core Features | 25% | BOM management, CAD integration, Change Control, and NPI workflows. |

| Ease of Use | 15% | UI intuitiveness, mobile accessibility, and search efficiency. |

| Integrations | 15% | Breadth of CAD, ERP, CRM, and SCM connectivity. |

| Security & Compliance | 10% | ITAR, GDPR, ISO 27001, and granular audit trails. |

| Performance | 10% | System speed with large assemblies and global multi-site sync. |

| Support & Community | 10% | Training resources, documentation, and user forum activity. |

| Price / Value | 15% | Total cost of ownership vs. operational efficiency gains. |

Which Product Lifecycle Management (PLM) Tool Is Right for You?

The right PLM choice depends on your “Digital Maturity” and your specific hardware ecosystem.

- Small Startups & Solo Designers: If you are a hardware startup with 1–5 people, OpenBOM or Autodesk Fusion Manage are your best friends. They provide immediate structure without the heavy administrative burden of enterprise tools.

- Mid-Market High-Tech Companies: If you manufacture electronics, Arena PLM is often the top choice because it already understands the “language” of chips and suppliers. If you are a Salesforce-centric company, Propel is the obvious winner.

- Large Manufacturing Enterprises: If you are building cars, planes, or medical equipment, you need the “Big Three”: Siemens Teamcenter, PTC Windchill, or Dassault Enovia. Your choice here usually depends on which CAD tool your engineers prefer (NX, Creo, or CATIA).

- Budget-Conscious but Technical: If you have an internal IT team that wants to build a custom-tailored PLM without paying upfront licensing fees, Aras Innovator is the standard-bearer for flexible, open-architecture PLM.

- The “Suite” Believers: If your business already runs on Oracle or SAP, look at their native PLM offerings first. The integration benefits usually outweigh the “best-of-breed” features of standalone tools.

Frequently Asked Questions (FAQs)

1. What is the difference between PLM and PDM?

PDM (Product Data Management) focuses strictly on engineering files and CAD versions. PLM (Product Lifecycle Management) is broader—it manages the business processes, BOMs, suppliers, and quality throughout the product’s life.

2. Does PLM replace an ERP system?

No. PLM manages the product design and engineering (the “What”), while ERP manages the execution and finance (the “How Many”). They should be integrated for a smooth design-to-production flow.

3. Can PLM software work on a Mac?

Most modern PLM tools are web-based (SaaS), meaning they run in any browser (Safari, Chrome) on a Mac. However, some older on-premise administrative tools still require Windows.

4. How long does a PLM implementation take?

Small SaaS rollouts (OpenBOM, Arena) can take 2–4 weeks. Large enterprise rollouts (Teamcenter) can take 6–18 months depending on the complexity of data migration.

5. What is an EBOM vs. an MBOM?

The EBOM (Engineering Bill of Materials) represents how the product was designed. The MBOM (Manufacturing Bill of Materials) represents how it will be built, including tools, packaging, and assembly instructions.

6. Is my data safe in a cloud-based PLM?

Yes. Modern cloud PLM providers (Autodesk, Propel, Arena) use higher security standards than most internal IT departments, including SOC 2, ISO 27001, and advanced encryption.

7. Can PLM help with environmental compliance?

Absolutely. Tools like Siemens Teamcenter and Arena have built-in features to track RoHS, REACH, and carbon footprint metrics for every component in your product.

8. Do I need a full-time administrator for PLM?

For enterprise systems like Teamcenter or Windchill, yes. For SaaS tools like OpenBOM or Fusion Manage, a part-time engineer or IT manager can usually handle the administration.

9. Can I use PLM for software-only products?

While you can, it’s not ideal. Software teams are better served by ALM (Application Lifecycle Management) tools like Jira. PLM is specifically designed for physical, “hardware” products.

10. What is “The Digital Thread”?

It is the seamless flow of data from the initial requirement to design, manufacturing, and field service. PLM is the platform that weaves this thread together.

Conclusion

Choosing a PLM tool is one of the most consequential decisions a manufacturing company can make. It is not just about choosing software; it is about choosing the digital foundation for your innovation. While Siemens Teamcenter remains the gold standard for sheer power, the rise of cloud-native tools like Arena, Propel, and Fusion Manage has democratized PLM for smaller, faster-moving teams. Ultimately, the “best” tool is the one that your engineers will actually use—because a PLM is only as valuable as the data it contains.